Upgrading your inventory management system from barcodes to QR Codes is like trading in your old, semi-reliable sedan for a fast, feature-rich sports car—except it’s way more cost-effective.

QR Codes were invented for inventory management, and they continue to be the gold standard for keeping track of products. The flexibility and affordability of this technology mean you can use QR Codes for small businesses just as easily as large enterprise brands.

Whether you’re keeping your local coffee shop stocked with filters and beans or managing one thousand warehouses across the world, QR Codes will make your life easier.

The evolution of inventory and asset tracking: From barcodes to QR Codes

QR Codes (short for Quick Response Codes) were originally created for inventory tracking in the automobile industry. The standard at the time was UPC barcodes, which had a lot of limitations. They were slow and unwieldy to scan, and they could contain only around 25 characters of data.

This new type of code changed the game. QR Codes can be read from any angle or distance, making them extremely quick to scan, and they can contain thousands of characters of data.

While QR Codes have been adopted for a variety of uses over the years, they are still a leading inventory-tracking tool.

Benefits of using QR Codes in inventory management

QR Codes have grown beyond their quick-scanning capabilities into a sophisticated tool. They excel at helping warehouses everywhere reduce database errors and optimize supply chains.

Quicker scanning and inventory data updates

The unique black-and-white grid patterns of QR Codes are behind their quick-scanning capabilities.

The grid’s pattern is designed to be recognized easily by a computer and can be scanned from multiple angles. This accounts for real-world errors—such as a QR Code sticker placed askew or a scanner angled not exactly right. It makes it much faster to capture and process the information, increasing work efficiency.

Plus, QR Codes can be scanned with mobile devices like smartphones, which are easier to handle in a warehouse environment than traditional barcode scanners.

Increased accuracy

The information density of QR Codes allows them to build in back-up features that can detect and correct data errors. For example, even if a QR Code is partially obscured, torn, or faded, it can still be accurately scanned.

This error correction is key in inventory environments, where the codes can be damaged from shipping and handling.

Versatility in various environments

QR Codes are incredibly versatile. They can contain any type of data. They can be used in many different spaces, and they can be printed, carved, or digitally displayed. Sometimes, they’re even carved into steel for damage resistance. This makes them suitable for large inventory systems with nuanced needs.

Better data management

Due to the amount of data QR Codes can store, the code can contain detailed inventory data that helps keep systems well-managed, efficient, and organized.

QR Codes can store any product information ranging from serial numbers to expiration date to color. Being able to store multiple points of data and automatically detect errors also results in cleaner, more accurate databases. Plus, that data can be analyzed for future business decisions.

Real-time tracking

QR Codes track scans and other data in real time. That means inventory databases stay up to date, so team members always have visibility into the location and stock of inventory items. You’ll be able to track assets and proactively detect inventory issues before they negatively impact your business.

How to implement QR Codes for effective inventory management

QR Codes fit right in with existing inventory systems and business processes. Some inventory systems even have QR Code support built-in, simplifying the switch. Here’s how to prepare for bringing your inventory system to the modern age.

Assessing your inventory needs

To choose the best system for your inventory management process, it’s important to understand how your inventory supports your business goals.

You should also assess what risks are associated with your inventory. For example, is your inventory perishable? Breakable? This will help you identify what types of data you need to track.

Choosing the right QR Code type

There are two types of codes: Static QR Codes and Dynamic QR Codes. Static QR Codes are unchangeable, and they can’t be tracked. Dynamic QR Codes are trackable, and the data in the code can be updated.

Dynamic QR Codes are usually the clear choice for inventory management, as you will want to be able to track scans. You may want to update the data in your QR Codes as inventory changes.

The benefit of Static Codes, however, is scanners don’t need an internet connection to read them. This could be important, depending on your inventory needs.

Designing and creating QR Code labels

Bitly’s QR Code generator software lets you create codes in seconds and customize them however you like. You can choose colors, patterns, and images to distinguish visually between different product categories. You can also promote your brand through custom QR Codes.

Integrating QR Codes with inventory management software

To keep a streamlined operation with updated databases, you’ll want to integrate your QR Codes with your inventory management system. Most systems are equipped to handle QR Codes, so you should be able to do this fairly easily.

Establishing a system for regular updates

For accurate inventory management, you should put protocols in place to regularly check your numbers. For example, every two weeks is a pretty average timeline for counting your inventory and updating the database.

Example applications of QR Code inventory management systems

QR Codes have proven useful for inventory management in a wide range of industries. Beyond the code’s humble automotive beginnings, it’s now used in spaces ranging from retail to healthcare, taking business operations to the next level.

Retail

Inventory is key in retail. With QR Codes, you can maintain accurate information about stock and the locations of items (for example, if an item is in a warehouse or store location in another city).

As a bonus, QR Codes are also great for engaging customers. Display codes throughout the store with links to online product promotions.

Healthcare

Tracking inventory of medical supplies is critical in a healthcare environment. Being able to manage resources makes it possible to efficiently distribute supplies, medical equipment, medications, and more.

QR Codes can link to these healthcare systems to track the levels and locations of inventory. The person scanning the code can easily pull up the item’s page in the system and see real-time inventory data, making it simple to order more supplies as needed or shift stock between locations.

Logistics and warehousing

The rich data in QR Codes for supply chain management, logistics, and large-scale inventory management is a game-changer. The precise, real-time data allows you to control and fine-tune your ordering and shipping approach.

For example, you can optimize how frequently to order perishable products, preventing waste while also never going out of stock. You can even pair your system with GPS for more precise location tracking.

Manufacturing

Manufacturing, especially when creating complex parts, really benefits from a QR Code system to more precisely track items. QR Codes are also useful for checking and updating equipment maintenance, allowing for better enforcement of risk compliance practices.

Libraries

Libraries are traditionally barcode users, but QR Codes can bring in an additional layer of data to help manage books and resources. The precision of QR Code tracking can help offer libraries richer data on product checkouts.

QR Codes are also a great way to engage library patrons by linking them to websites or directing them to a page with pre-populated order forms.

Event management

QR Codes have been a game changer for ticket management, but event managers can use QR Codes for inventory, too. Event managers need to be able to deliver supplies to venues, as well as track equipment. Complex events also need to track precise product information to prevent loss.

For example, Taylor Swift’s Eras Tour has to track equipment, props, costumes, and instruments for a three-hour show across dozens of cities in countries spanning multiple continents.

While we don’t know what tracking system Taylor is using, this is a perfect use case for QR Codes paired with GPS technology and detailed data tracking.

The future of inventory management with QR Code technology

QR Codes continue to become more useful and efficient with new technological developments. As AI, robots, and more enter the world of inventory management, QR Codes will be able to help usher in the future.

Integration with the Internet of Things (IoT)

IoT could change the way you track inventory. Connected sensors and tracking devices could keep an eye on products in mid-transit.

The devices would update databases in real time and monitor product conditions like temperature, humidity, and air pressure. Paired with QR Codes to track conditions and GPS coordinates, IoT will be a powerful tool for protecting stock.

Data analytics and machine learning

Integrating QR Codes with machine learning technology can allow businesses to automate many aspects of the inventory management process. For example, say you add QR Codes to your inventory items. When the codes link to your inventory management software, ML algorithms can analyze any patterns in historical use, identify and optimize reorder schedules, and even trigger automatic order workflows when inventory reaches a certain threshold.

Drone-based inventory management

Companies have been experimenting with drones for inventory management and delivery for some time. Major hybrid retail brands like Amazon have been developing delivery drones for a decade. Drones equipped with QR scanners could be the next breakthrough.

Because QR Codes can be scanned from multiple directions, drones could handle the easy scans. In warehouses, drones would be able to continuously track stock levels and product locations with high speed and efficiency.

Embracing the future of inventory management with Bitly’s QR Codes

QR Codes have streamlined inventory management across a variety of industries. Whatever you need to track, QR Codes are sure to fit into your workflow with efficiency and ease—and Bitly is here to help with the transition.

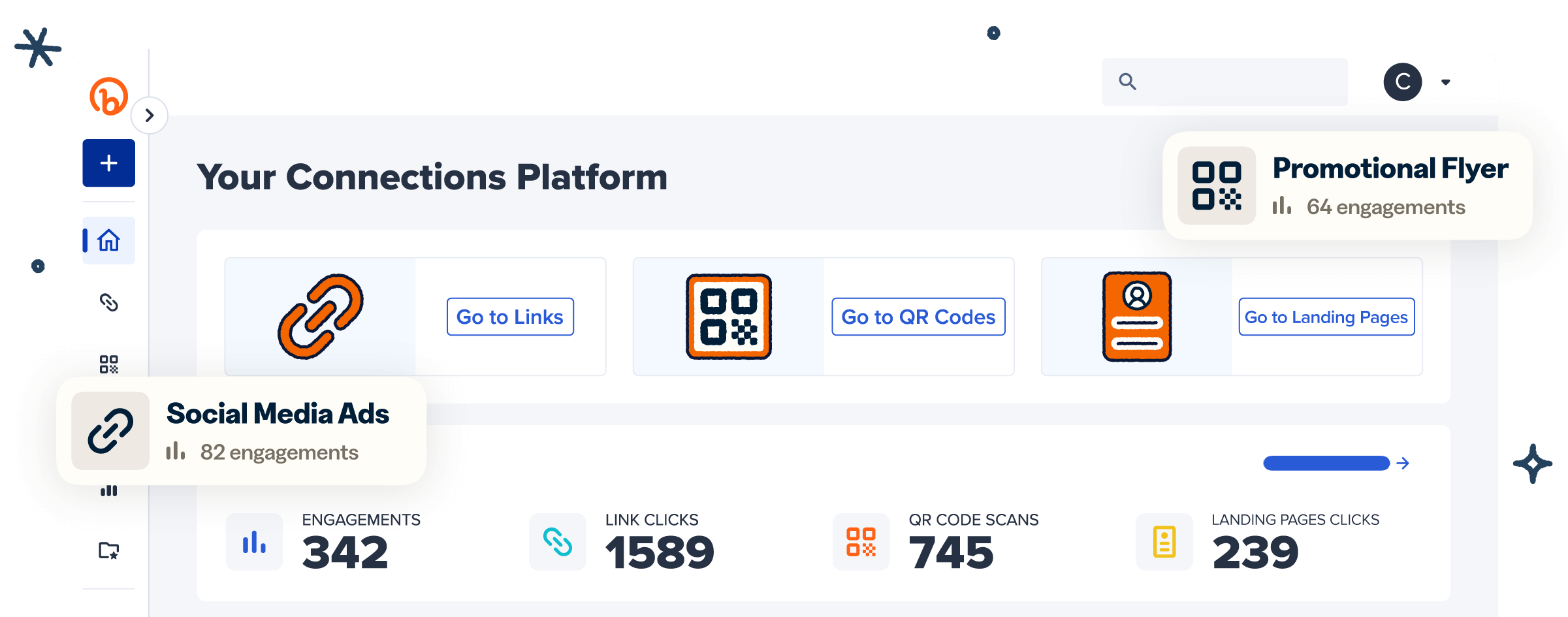

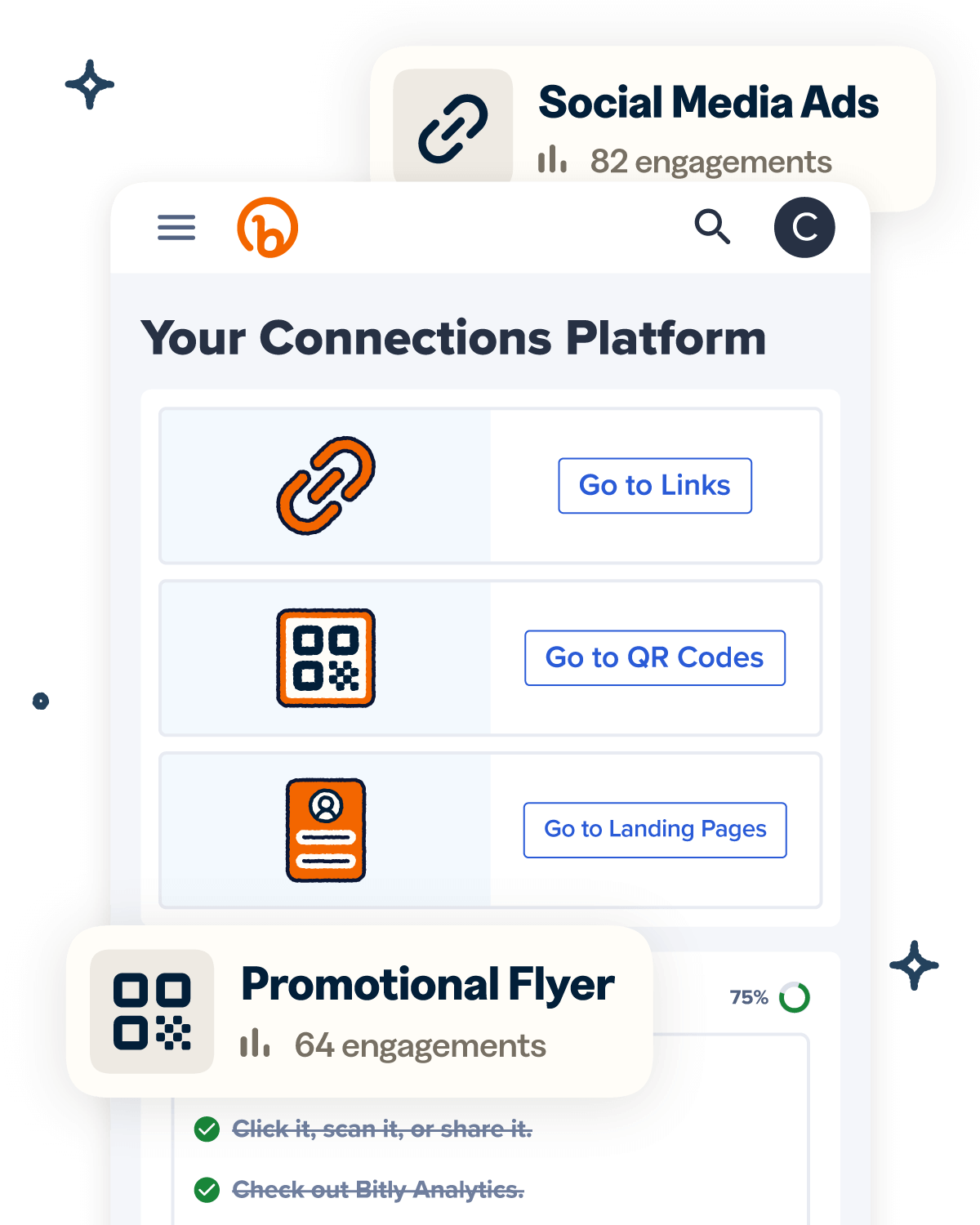

You can make a QR Code using Bitly in seconds, and Bitly offers the most advanced features to make your life easier, including QR Code generation, customization, and analytics for Dynamic Codes.

See how Bitly can take your inventory management system to the next level—find the right solution for your business today!